Cleanroom Production

Cleanroom production capability from Southbourne Rubber is fully certified to meet the varying requirements of the components, applications and customer requirements

We support the varying needs of UK and global manufactures with a vast rubber and silicone component range. Combined with our cleanroom production capability we can provide the exacting standards for industries such as healthcare and aerospace.

Our UK based facility is fully certified to ISO Class 7 and enables us to offer an industry leading resource. Our attention to quality across the component manufacturing, handling and packing process enables us to support key medical and aviation manufactures.

Our production and cleanroom facilities are fully scalable. We deliver one-off prototypes, small production runs and fulfil high volume all with absolute precision and quality.

Expertise and understanding within SBR’s technical and production teams has in turn in advanced our capability above other part suppliers

Expertise and understanding within SBR’s technical and production teams has in turn in advanced our capability above other part suppliers

Our production and cleanroom facilities are fully scalable. We deliver one-off prototypes, small production runs and fulfil high volume orders all with absolute precision and quality

Product Focus: Cleanroom Production & Packing

Our rubber component production and packing services help to streamline your own manufacturing and assembly. You can be assured of the reliability of parts and hygiene specification demands of your application

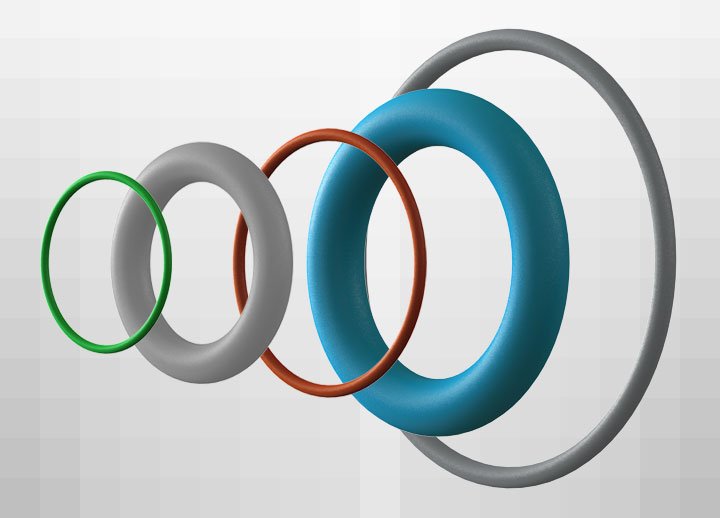

A large number of our components with this added specification are in high demand, particularly our range of O-rings. All sizes, rubber and silicone material specifications and volumes are available.

Most O-rings are made out of synthetic rubber that has been designed to withstand the high temperatures and extreme conditions of aerospace applications. This characteristic is the reason they are used in aircraft and even space shuttles.

Medical devices such as IV and implant components also rely on this component. Designed for hygiene-critical environments, they are typically made from medical-grade rubber. This enables them to be heat and chemical-resistant, prevents cracking, bacteria and toxicity.