Welcome to Southbourne Rubber Ltd (SBR°), a leading provider of precision elastomeric sealing products.

With a strong reputation built around our flexibility, technical expertise, and exceptional customer service, we are committed to providing high-quality products and solutions to our valued clients.

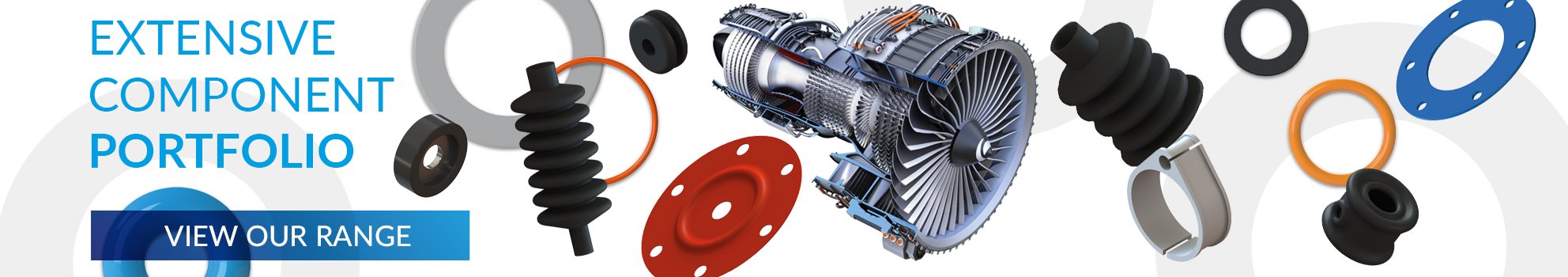

Our extensive component portfolio includes both standard and make-to-print products, ensuring that we can meet the specific needs of our customers. With over 40 years of experience in the aerospace sector, we have a deep understanding of the industry and the products required to support our customers' platforms.

Approved to both aerospace standard AS9100D and ISO9001:2015. Click for our quality accreditations and customer approvals.

Our bespoke components give customers the tailor-made solutions they are looking for from a single source.

Specialists in custom mouldings, we utilise our technological and industry knowledge to support our customers with make-to-print, NPI and design work.

We produce from some of the most advanced materials available, ensuring superior operational performance and safety. Our solutions include critical tolerances, design support and material expertise.

We take pride in supporting a wide range of key industries with our precision elastomeric sealing products, including aerospace, defence, energy, medical, marine, and engineering.

However, our strong presence in the aerospace sector is something we're especially proud of, with many years of experience in this field. We have established ourselves as a trusted supplier to both global and British aerospace, whether in commercial or military applications.

Our extensive product portfolio includes both specialist and standard products, making it possible to meet the specific needs of our customers. These products can be found across a range of critical applications, including avionics, actuation, landing gear, interiors, fuel control and engine systems, as well as other hydraulic and pneumatic applications.