Finite Element Analysis

Finite Element Analysis (FEA) requires an understanding of technical and engineering considerations all available at SBR

This computerised method allows us to make predictions on how one of our components will react and perform. A component when placed within a system or environment will be exposed to stresses, strains and environmental conditions.

The variables a rubber or silicone component is exposed to are viewed as a collaboration of effects. These include load pressure, temperature exposure, vibration and fluid flow.

Considering these field variables is vital to the performance and longevity of the part and the systems it operates within.

The process of FEA at Southbourne Rubber will indicate locations of weakness, potential breakage points, component longevity and overall part performance for its designed application

The process of FEA at Southbourne Rubber will indicate locations of weakness, potential breakage points, component longevity and overall part performance for its designed application

A component when placed within a system or environment will be

exposed to stresses, strains and environmental conditions

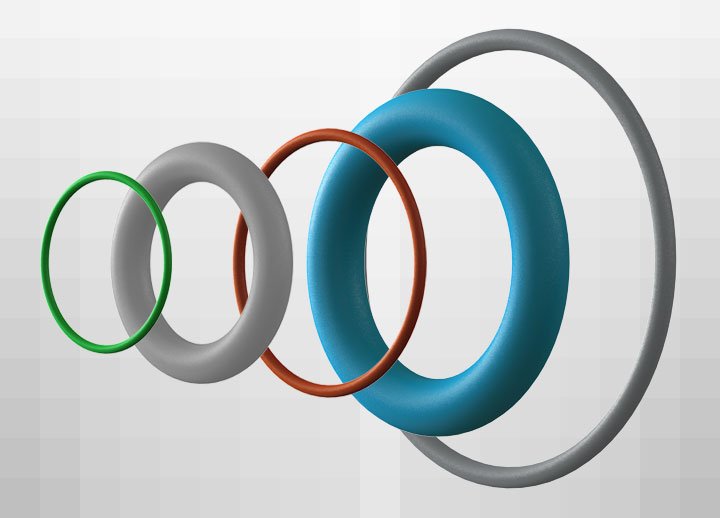

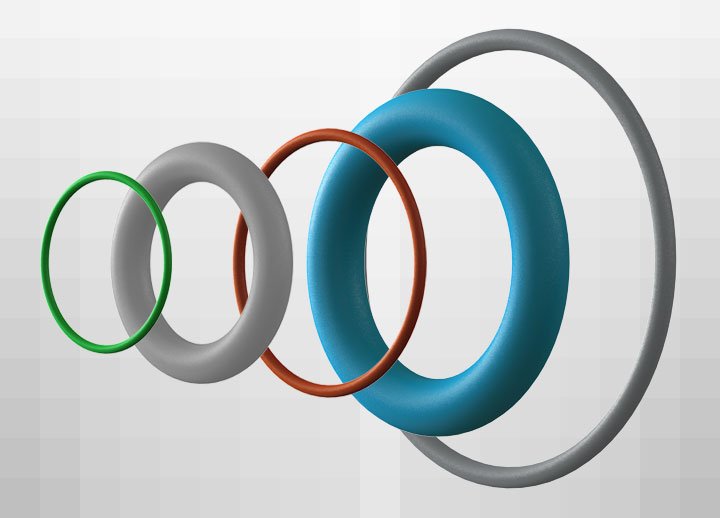

Product Focus: SBR O-rings are an example where FEA is applied to ensure the highest component quality and performance excellence

Many aircraft manufacturers use O-rings as a seal in hydraulic systems for brakes or integrated into wing flaps and landing gear for example. These are highly demanding applications and require absolute quality and reliability to ensure maximum safety.

Most O-rings are made out of synthetic rubber that has been designed to withstand the high temperatures and extreme conditions of aerospace applications. This characteristic is the reason they are used in aircraft and even space shuttles.

Hydraulic rescue tools, which help release people trapped in vehicles after crashes, and medical devices such as IV and implant components also rely on this component to work.

In addition to AS9100D and ISO9001:2015, SBR are approved by the WCS World Certification Service who are ANAB Accredited. The company is compliant to AS13003 and AS13004, PFMEA and MSA.